Chongqing- China's manufacturing industry is accelerating towards intelligence, and Chongqing takes advantage of its solid industrial foundation, industrial robots, and digital empowerment to promote industrial upgrading and smart manufacturing.

The electronics industry is stereotyped as labor-intensive, with employees sitting on assembly lines repeating the same physical tasks. Chongqing no longer has such a scene, although it was quite common in the past.

Chongqing E-ong Optoelectronics Technology, a company in Chongqing's Liangjiang New Area, has successfully built 35 SMT (Surface Mount Technology) production lines in recent years, mainly engaged in R&D, and production of LCD module control boards, RFID (radio frequency identification), and car kits.

Several workers gathered around an FCT (functional test) automatic testing equipment on a new SMT line to debug it.

According to Gao Geng, production manager of Chongqing E-ong Optoelectronics Technology, intelligent devices bring business benefits. He made a simple comparison: manual testing of circuit boards increased labor costs and quality control errors; after using automation equipment, labor costs dropped, and qualified rates improved to 99.98%.

As the electronics industry upgrades, so too is the automobile industry becoming high-end, intelligent, and green.

SERES Liangjiang Intelligent Factory. (Photo provided to iChongqing)

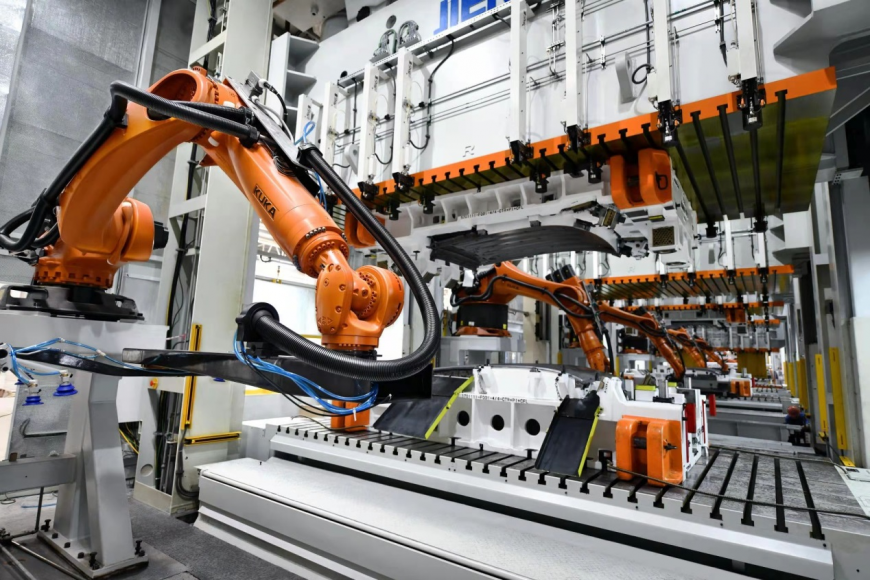

Entering SERES Liangjiang Intelligent Factory, only a few people on the production line.

In the stamping workshop, after parts are processed, a robot arm grabs them and transfers them to the following process.

As part of the welding workshop, 1,000 intelligent robots are equipped with the German Zeiss vision system, and nearly 100 Automated Guided Vehicles (AGV) robots are precisely connected with mechanical arms. In the assembly workshop, robots automatically glue and install the front and rear windshields of the car.

AI, IoT, and cloud computing are among the technologies that SERES believes can be integrated into the intelligent factory to guarantee high-quality delivery and meet users' customization needs.

SAIC Hongyan Smart Factory. (Photo provided to iChongqing)

SAIC Hongyan Smart Factory uses digitalization to increase efficiency, improve quality control, and reduce energy consumption and pollution.

In the intelligent welding workshop, welding robots replaced labor. With a welding group control system, welding quality can be tracked in real-time, improving flexibility and operating efficiency.

The person in charge of SAIC Hongyan said that upgrading equipment and systems had increased the production efficiency of the entire welding workshop by 44%. The assembly workshop built a new chassis air conveyance corridor and introduced uncrewed AGV trucks.

As of the first half of 2022, Chongqing's automobile industry records gratifying achievements, with an industrial added value of 9.1% and a substantial increase in the output of new energy vehicles of 1.7 times. New car models such as AVATR E11 and Wenjie M5 were also launched.

By continuing to browse our site you agree to our use of cookies, revised Privacy Policy and Terms of Use. You can change your cookie settings through your browser.

For any inquiries, please email service@ichongqing.info