By Yuling Chen, EDITOR

“Robots have improved production efficiency, increased the product qualification ratio and reduced the production costs.” These days, the reporter often hears such words in three automobile enterprises which belong to joint ventures, state-owned enterprises, and private enterprises respectively.

At present, based on the requirements of a high-quality development, many traditional enterprises in Chongqing have implanted such “smart factors” as digital workshops and intelligent factories in their whole production process.

SAIC Hongyan

As the welding gun sizzled with sparks, more than 20 robots swung their arms up and down. In a short time, a robot had welded a complete cab shell of a heavy truck.

According to Sun Yu, Supervisor of the pre-welding process development of SAIC Hongyan, there are 25 robots in the whole production line. At present, in addition to manual feeding, robots will complete all other processes including the assembly, welding, and transportation in the welding workshop.

After SAIC Hongyan put this production line into use, it achieved a great improvement in production efficiency. Previously, 30 workers could produce 11 wheelhouses per hour, but now, 6 workers can produce 15 wheelhouses per hour by operating the robots.

Lou Jianping, General Manager of SAIC Hongyan, said that they planned to invest RMB 2 billion in the next five years to carry out an intelligent “overall transformation” of production lines. SAIC Hongyan will construct “unmanned workshops” after it completes the three phases of the project and puts them into use in 5 years.

Chang’an Automobile

Robots are everywhere in the stamping, welding, and coating workshops in the manufacturing base of Chang’an Automobile in Liangjiang New Area. The entire production process in the stamping workshop almost needs no manual labor, and robots and stamping machines will jointly complete all the work.

“Intellectualization is a new opportunity for automobile enterprises to achieve positive development,” said Zhu Huarong, President of Chang’an Automobile. To install “smart brains” for automobile manufacturing, the R&D personnel of Chang’an Automobile have conquered more than 100 core technologies. The L4-level unmanned vehicle of Chang’an Automobile has achieved the first demonstration operation in China and is expected to achieve mass production in 2025.

According to Zhu Huarong, Chang’an Automobile is the innovative intersection carrier of such fields as artificial intelligence, industrial Internet, 5G iteration, and intelligent manufacturing. Therefore, the intelligent connected vehicle oriented toward autonomous driving will be the next “smart” development direction of Chang’an Automobile.

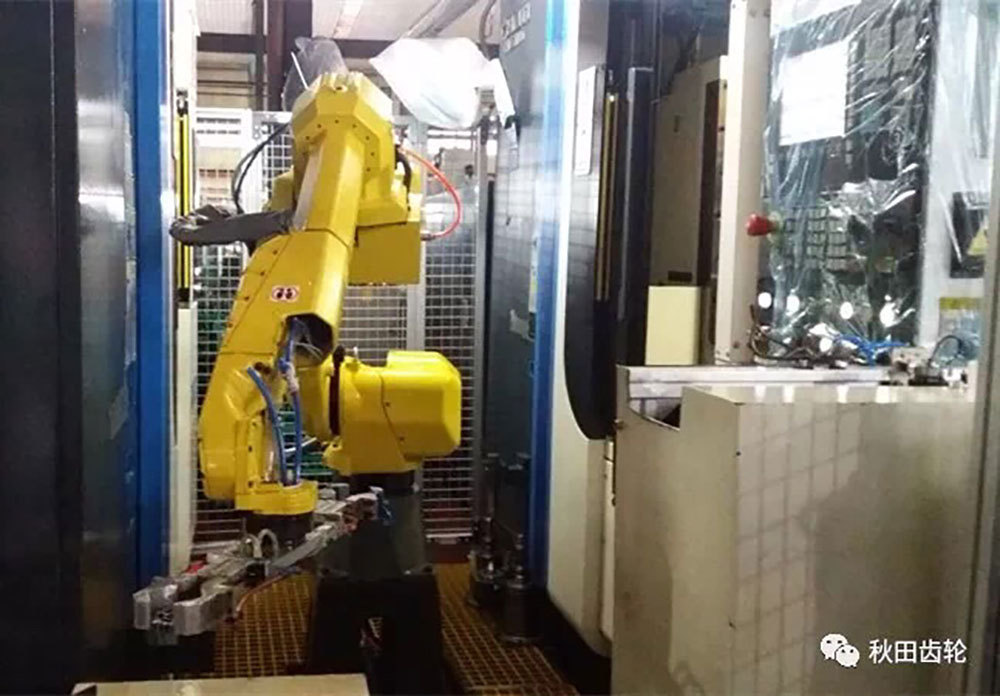

Akita Gear

“To achieve the goal of enterprise transformation and upgrading, we need to adopt a variety of methods like technological transformation and product structure adjustment,” said Liu Yi, President of Akita Gear. Akita Gear has made four goals of transformation and upgrading, including the upgrading from the production of low-end gears to high-end products and the transformation from motorcycle gears to automobile gears. Additionally, it will also promote the transformation from the domestic market to the international market and the upgrading from the traditional processing to automatic processing.

Liu Yi said, “The implementation of the intellectualized transformation will help new production processes and equipment to replace the original outdated ones, so as to promote high quality with intelligence and to better meet the market demands.”

In 2018, Chongqing launched a campaign of “replacing manual labor with robots” among enterprises in the city by introducing the implementation plan of intelligent manufacturing.

“This year, Chongqing will continue to implement the intelligent transformation, and it will still focus on promoting the “replacement of manual labor with robots” and implementing the information system integration applications,” said the principal of Chongqing Economic and Information Technology Commission. In 2019, Chongqing schemes to launch the identification and application of the first batch of digital workshops and intelligent factories and identify 100 of them. It aims to promote the intellectualized transformation of 500 enterprises by accelerating the “replacement of manual labor with robots”.

According to the plan, by 2022, 5,000 enterprises in Chongqing will achieve the intelligent transformation, and more than 84% of the city’s industrial enterprises above the designated size will enter the stage of digital manufacturing. In addition, over 64% of the industrial enterprises above the designated size will enter the stage of digital and networked manufacturing.

Source: CQCB

By continuing to browse our site you agree to our use of cookies, revised Privacy Policy and Terms of Use. You can change your cookie settings through your browser.

For any inquiries, please email service@ichongqing.info