Chongqing- The Zhengzhou-Wanzhou high-speed railway entered trial operation in April, and it will soon open to traffic when the Zhengzhou-Wanzhou high-speed railway is operated in June. The Chongqing section of the high-speed railway is the longest single-hole double-track tunnel in Asia. It boasts a total length of more than 18.9 kilometers and a train speed of 350km per hour.

All the Lesser Three Gorges Tunnel project staff celebrate the tunnel's transfixion. (Photo provided to iChongqing)

The Zhengzhou-Wanzhou high-speed railway has been selected as one of the 36 super projects in China. It is the most challenging and risky railway in global high-speed rail.

It is called the "subway type" high-speed railway. In particular, the bridge-tunnel ratio of the Chongqing section of the Zhengzhou-Wanzhou highspeed railway has reached a whopping 98.1%. In this section, the Lesser Three Gorges Tunnel, with over 18.9 kilometers, is the longest single-hole double-track tunnel in Asia. It has the most complex geological conditions and the highest risk, including karst, crossing reservoirs, large water inflow, high water pressure, and other problems. It is a class I high-risk tunnel.

"The Lesser Three Gorges Tunnel is a high-speed railway tunnel, which requires a larger turning radius, and it must have such a long tunnel to pass through the Three Gorges hole area. We did extensive research early to ensure the project was the least difficult to implement and the least damaging to the environment," said Liu Baolin, chief engineer of the tunnel department of China Railway Eryuan Engineering Group Co. Ltd.

The Lesser Three Gorges Tunnel is located deep in the Three Gorges Reservoir area. The entrance and exit of the tunnel are river channels and cliffs. So it didn't allow construction from the entry and exit of the central hole. The design can only adopt the auxiliary tunnel of three pedestrian crosswalks plus two inclined shafts. In the way of parallel heading construction in the karst section, the cumulative total length of the auxiliary tunnel reaches 15.44 km.

The Lesser Three Gorges project team of China Railway Tunnel Group Co., Ltd carried out mechanized construction in the tunnel. (Photo provided to iChongqing)

The tunnel passes through unfavorable geological structural belts such as the Qiyao Mountain anticline and the Bawu River syncline. There is specific unfavorable and complex geology, like karst, expansive rock. It may pass through the formation that contains natural gas. So the construction is complicated, and the safety risk is high.

To ensure the security of the construction, the team adopted the class I mechanized supporting construction method. This includes a three-arm rock drilling rig as the leader, equipped with a wet spray unit, hydraulic self-moving inverted arch trestle, automatic pouring formwork trolley, integral mobile trench jumbo, semi-automatic spray maintenance bench, and other advanced technology and equipment. The complete tooling and equipment meet the fundamental guarantee for the simultaneous excavation of more than ten operation lines in the tunnel.

The exploration team predicts a huge amount of water gushing from the tunnel. The maximum water gushing is 168,000 cubic meters per day, equivalent to 60 standard swimming pools (2,500 cubic meters). During the investigation of the surface geological conditions in the tunnel, the team found 152 discharge points such as fissure water, pore water, spring water points, and underground river outlets, of which 12 are underground river outlets.

Water gushing from a water-eroded groove in the Lesser Three Gorges Tunnel. (Photo provided to iChongqing)

The project incorporates advanced forecasting into procedural management, predicts karst risks in advance, and formulates drainage plans to be prepared to fight difficulties in various karst caves.

The construction team detected an oblique karst cave in a particular section during the excavation. The cave mouth is about 7.5 meters wide and 10 meters long. The depth of the on-site hanging rope can be measured at about 55 meters, which is equivalent to the Leaning Tower of Pisa. After two years of hydrological observation, the team found water gushing in the cave all year round, and the surface water is closely connected with the cave water. The maximum water gushing reaches 29,290 cubic meters per day, enough for 15 standard swimming pools.

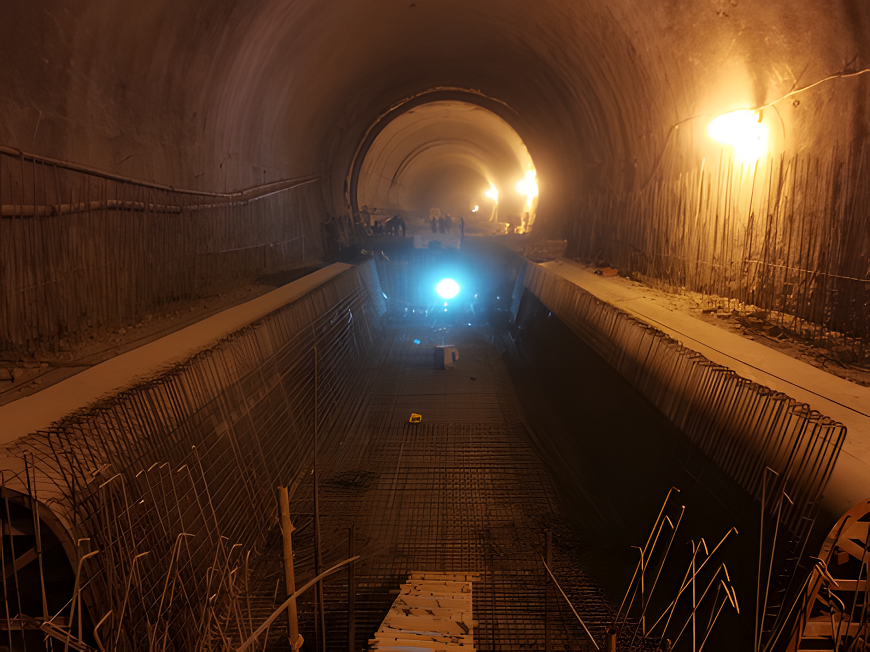

Box girder reinforcement installation in the Lesser Three Gorges Tunnel. (Photo provided to iChongqing)

To this end, the team set up a unique structure in the tunnel. They set a pile foundation joist structure at the lower part of the sidewall to span the karst cave and two water diversion tunnels. The tunnel bottom spans the karst cave with a box girder structure, and the bridge uses 24 meters of cast-in-place post-tensioned prestressed concrete supported box girder.

By continuing to browse our site you agree to our use of cookies, revised Privacy Policy and Terms of Use. You can change your cookie settings through your browser.

For any inquiries, please email service@ichongqing.info